Cluster 1

C1: MC-Based Design, Monitoring, and Control of Bioprocesses

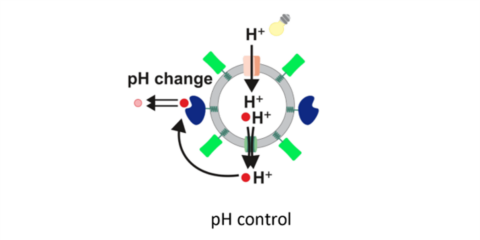

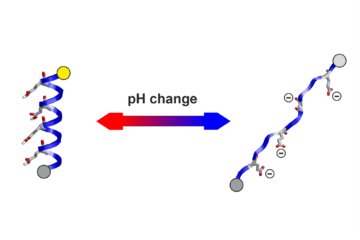

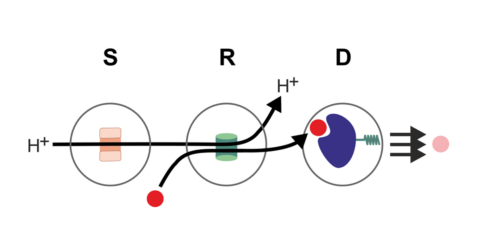

In the highly interdisciplinary field of industrial biotechnology, natural scientists and engineers work hand in hand to enable sustainable syntheses of complex molecules in an atom-economic manner. Hereby, developing ‘greener’ synthesis processes with lower atom consumption and generation of hazardous substances through the smart design of innovative production processes is currently one of the greatest challenges. In this context, enzymatic cascade reactions have proven to be highly effective tools but biocatalytic processes are often criticized for their long development times and time to market. Miniaturization and parallelization are powerful approaches to significantly accelerate the implementation and optimization of biotechnological processes with minimal consumption of expensive reagents . Due to the high importance of chemical reaction control for the performance of such processes, miniaturized systems must offer the same process control options as large-scale reactors, most importantly pH regulation and substrate feeding. Thus, acquisition of bioprocess information from uncontrolled batch reactions, e.g., in simple microwell plates, is unsuitable for a reliable scale-up. However, the development of suitable micro-scale bioreactors is hampered by the lack of appropriate tools for controlling reactions in microliter volumes (i.e., at nm-mm scales) with high precision. In C1, we will demonstrate for the first time that MC and the corresponding modelling techniques can play a crucial role for the design, monitoring, and control of bioprocesses. In particular, in P1–P3, we will investigate the nanodevices, the embedded rationally designed protein modules, and the MC models and algorithms needed for the control of reactions in microliter-scale bioreactors, respectively.